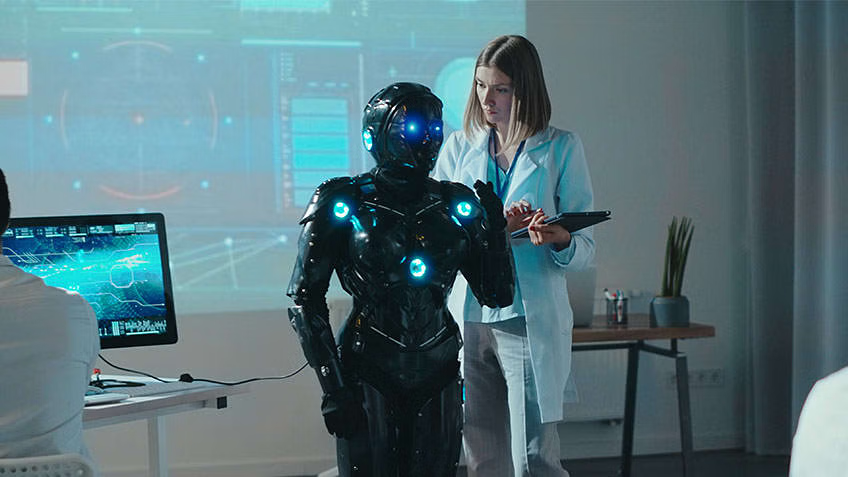

Robotics: Explore the use of robots in industries like manufacturing, healthcare, and automation

Even more essentially, regardless of the way that the “lights-out” modern office is at this point a remarkable quirk, the related motorization Robotics developments that structure the groundwork of Industry 4.0 are comprehensively and continuously conveyed. They are making huge differentiations in the gathering of numerous sorts of things and\, in adventures like clinical consideration, even the plan of organizations.

Occupation of robots:

The usage of Robotics in gathering has been on the rise since the 1960s, when they were first introduced as a part of what technologists call Industry 3.0 (described by programmable reasoning and significant level collecting). Robotics experienced youth in the vehicle business, where they were used in a general sense to weld vehicle bodies together. As progressions were created, associations began including robots in various locales, as composed factors and the clinical and food organizations. Starting in 2006, more robots were used outer the vehicle business than inside it.

The longing to lessen or wipe out the “three Ds” — dull, perilous, and grimy positions — was the essential driver behind the ascent of modern Robotics. In any case, other huge drivers consolidated the prerequisite for consistency of significant worth and consistency of stream in the gathering.

Today, Robotics are used in gigantic collecting and arranged tasks workplaces, but in light of the approaching of more unobtrusive, more sensible, and easy-to-use agreeable Robotics (“cobots”)- in little and medium-sized associations too.

Among the upsides of mechanical robotization are:

Robotics satisfy the need for excellent merchandise at a lower cost by making item quality more reliable and smoothing out creation lines.

They keep laborers from being expected to perform perilous, drawn-out, and dull errands.

The present related, or Industry 4.0, Robotics can dependably deliver data on parts stream and cycle quality data that man-made thinking or old-school data assessment can use to work on both a plant and gathering processes.

Due to more conspicuous characteristic flexibility than phenomenal machines or other hard robotization, Robotics enable additional unmistakable things minor takeoff from a lone line and-when composed with methodologies systems in Industry 4.0 courses of action engage plants to make varieties considering the client’s choice of preconfigured decisions (much of the time suggested as “mass customization”).

Since robots cost essentially comparable to any place in the world, they can help associations restore creating position that were moved to negligible cost work countries and all around even the chances.

Huge scope assembling to mass personalization:

The fourth point that related to Industry 4.0 advances, including robots, let creators mass modify their things like never before merits looking at comprehensively. We ought to acknowledge buying a vehicle for example: Various perusers of this article grew up under Industry 3.0, which went with the rise of handling in business.

During the 1970s, 1980s, and 1990s, purchasing a vehicle regularly required either picking a make and model at a vehicle sales center or on the other hand, in the event that nothing in the display area fit the bill, requesting a vehicle in a particular tone and with specific additional items like cooling. Point of fact, that was a lot of choices stood out from what Henry “for whatever length of time it’s dull” Portage offered of real value (i.e.,

Industry 2.0). Nevertheless, it was not the least bit like “planning” a vehicle online today.

Vehicle buyers as of now have such incalculable decisions to peruse that any permitted client has a good chance of ending up with a vehicle that basically has every one of the reserves of being stuck out. Presently, on the off chance that you own this vehicle and live in a city with, say, a portion of 1,000,000 individuals, and no other person has a vehicle like it, you are driving a vehicle that seems as though it was made only for you. regardless of whether you have 1,000,000 bucks. Whether or not it’s everything except a particularly expensive vehicle.

Driven by a hankering to make sensible, magnificent things that basically give the presence of uniqueness, the current mass customization is by and large engaged by Industry 4.0 developments including Web relationship between display area mentioning systems, creation network structures, and, shockingly, the robots on the vehicle handling plant floor.

The client seeks choices from a created summary of decisions. This plan of choices is planned and stuffed in the ideal solicitation. The truck shows up at the auto-producing office without a moment to spare. Likewise, the forklifts pass the parts straightforwardly onto the mechanical creation framework station where the client’s “unique” vehicle appears.

Specifically, the mass customization depicted above and engaged by Industry 4.0 isn’t adequate. since clients want more. They need mass personalization, which should be had when the human touch returns to the gathering. This is the very thing that I call Industry 5.0.

Conclusion:

Truly, there are epic areas of thing types that nobody needs redid, and for which Industry 4.0 courses of action, with their regular current robots, are magnificent. A tweaked drywall anchor, motor block, or lawnmower cutting edge is incredible. In case these things can be made at an irrelevant cost in a lights-out assembling plant, it benefits everyone.